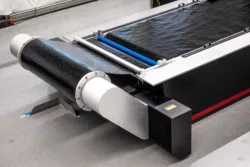

Automated Seam Welding

OFF-AXIS/BIAS PLY ROLLS ON AN INDUSTRIAL SCALE

In the process of automated seam welding (ASW), conventional rolls of UD tapes, with fibres in the longitudinal direction of the roll, are transformed into rolls with fibres in 90°, 45° or -45° directions. These so called off-axis/bias ply rolls can then be processed in Continuous Compression Molding (CCM) or Double Belt Press (DBP) consolidation processes. This replaces the common labor intensive manual seam welding process.

- Automation of a highly labour-intensive process

- Strong and fast weld using continuous ultrasonic welding technology

- Applicable on an industrial scale (mass production)

Features

- Continuous ultrasonic welding technology

- Maximum overlap 2.54 mm (0.1″)

- Real-time overlap verification

- Variable input tape width

- Customised off-axis/bias ply tape widths

- Up to 325 m2/hour