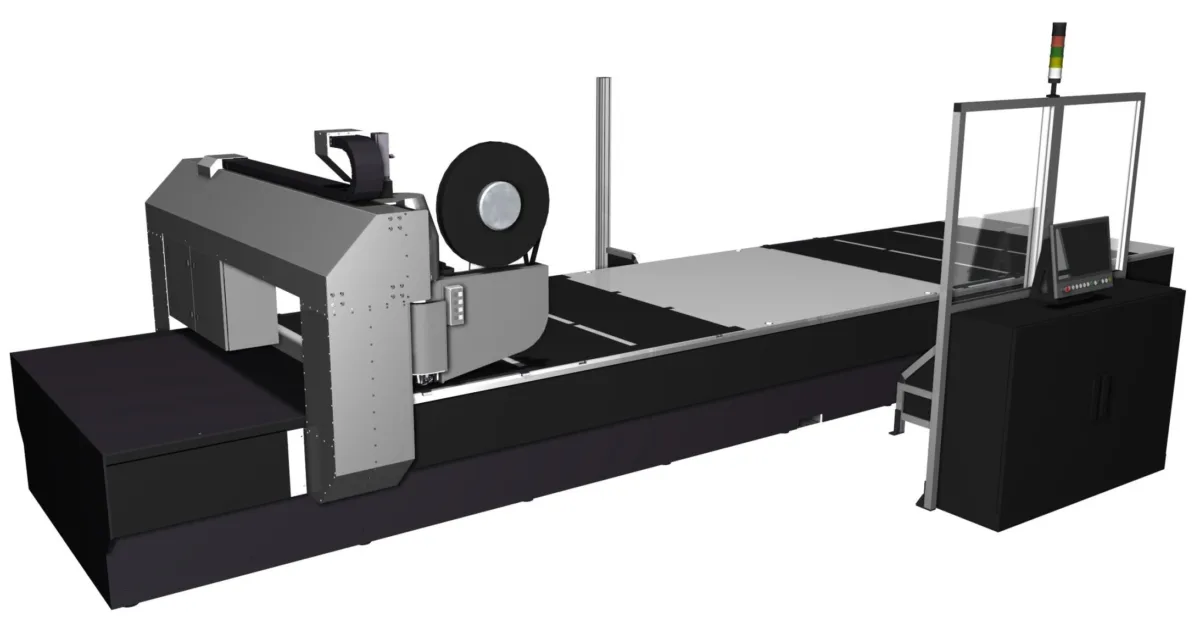

The FALKO Automated Tape Layer produces thermoplastic composite laminates and near-net-shape products. The continuous ultrasonic tacking technology allows safe, reliable and efficient high output production. While the AngularCut technology minimizes the waste during production by cutting individual UD tapes at various angles. The FalkoCAD (CAM) software ensures that all angular cutted UD tapes fit together on a ply. The embedded real-time gap verification system, verifies the gaps between tapes during layup. This makes the FALKO ATL an efficient automated solution for thermoplastic composite components production.

- High production capacity

- Laminates of excelling quality

- Minimum waste of valuable material by AngularCut technology

High production capacity

FALKO Automated Tape Laying (ATL) is an advanced technology that enables the production of large thermoplastic composite laminate layers and near-net-shape products. With continuous ultrasonic welding, FALKO ATL facilitates safe, reliable, and efficient mass production. With a production capacity of up to 350 m2 per hour, FALKO ATL is a groundbreaking innovation in the mass production of thermoplastic composite parts.

Superior quality laminates for consolidation

FALKO's technology focuses on addressing the high costs associated with thermoplastic composite applications. By processing unidirectional (UD) tapes into semi-finished products, FALKO eliminates the need for time-consuming steps in consolidation processes. This makes the technology ideal for sectors such as aviation and automotive industries, where weight and strength are crucial factors.

Minimal waste of valuable material

FALKO's advanced process ensures minimal waste of valuable materials, contributing to cost-efficiency and sustainability. By using cutting techniques to remove defects from the UD tapes and prepare them for tape laying, FALKO achieves optimal utilization of the composite material. The CAD/CAM software, FalkoCAD, determines the best tape laying strategy, while a real-time gap and laminate verification system ensures the highest quality standards during production.

Unleashing the potential

FALKO is the result of extensive research and experimentation with various technologies. By combining cutting, automated tape laying (ATL), automated fiber placement (AFP), and ultrasonic technology, we have achieved a unique and groundbreaking innovation. This innovative approach allows us to process UD tapes into lightweight and strong semi-finished products with exceptional quality.

The highest achievable quality standards

With the integration of FalkoCAD CAD/CAM software, we can accurately determine the optimal tape laying strategy. Additionally, the real-time gap and laminate verification system continuously monitor the entire laminate structure, verifying the position of each individual UD tape during production. This guarantees the highest achievable quality standards and gives you full confidence in the end product.

Features

- Continuous Ultrasonic Tacking Technology

- AngularCut Technology

- Real-time gap verification

- Mass production up to 450 m2/hr

- High quality that meets the aerospace standard

- User friendly interface

- Intelligent Windows®-based FalkoCAD CAD/CAM application

- High precision gantry robot

- 21.5″ inch multi-touch screen

- Integrated safety system with safety control and light curtains